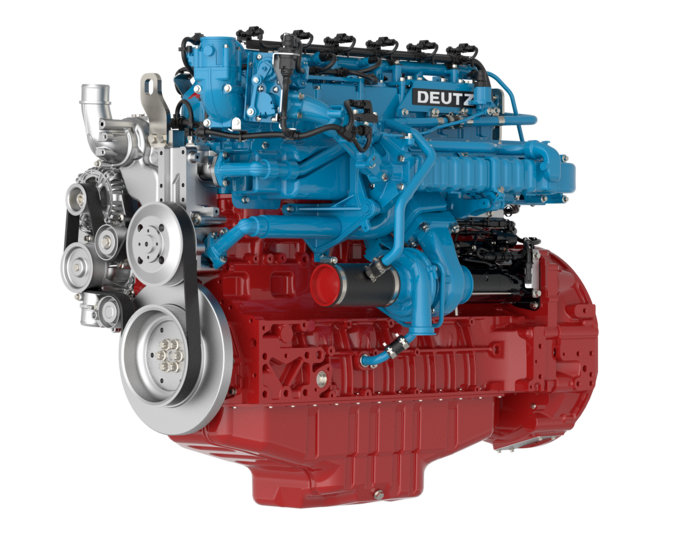

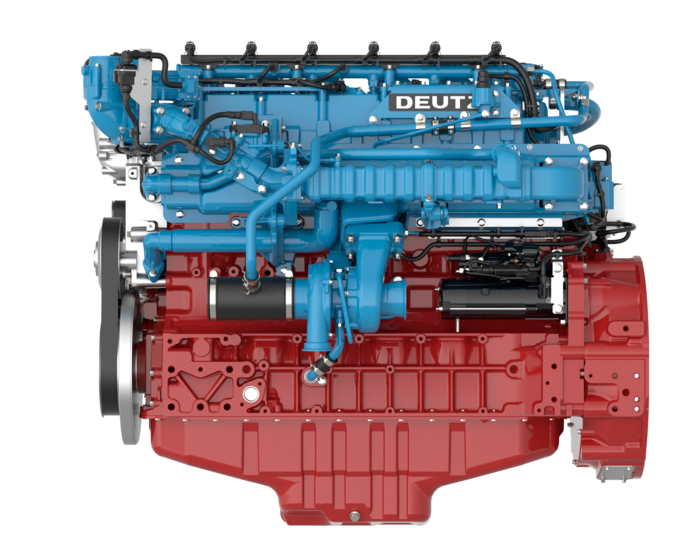

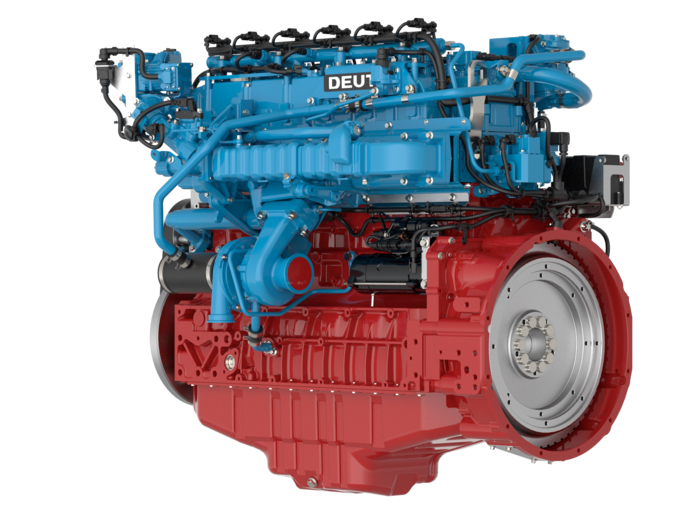

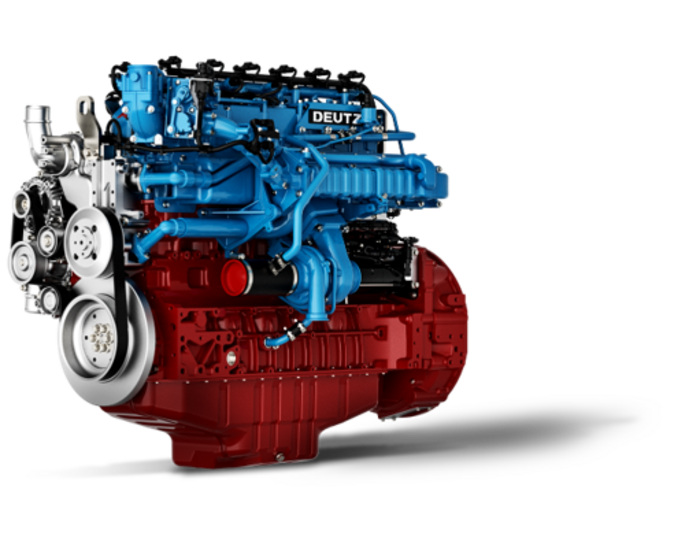

DEUTZ TCG 7.8 H2 – Hydrogen engine

Technology of tomorrow

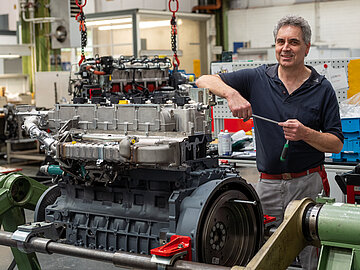

in production today

As demand for sustainable drive solutions grows, attention is increasingly turning to hydrogen as an alternative fuel. As a result, the hydrogen engine has an important role to play in decarbonizing the off-highway segment.

Runs like a Diesel. Only without the diesel.

The TCG 7.8 H2 is based on the DEUTZ diesel engines that have proven themselves millions of times over - except that it burns hydrogen. The six-cylinder engine delivers maximum dynamice capability an can effortlessly handle a wide range of load profiles. Unlike the fuel cell, it is - like all DEUTZ engines - resistant to extreme temperaturs, vibrations, solar radiation, and dust. and the good news is that this innovative drive solution is already in series production.

KEY FEATURES AT A GLANCE

- Energy efficient: offers optimal energy efficiency combined with the maximization of dynamic response using state-of-the-art components

- Powerful performance: optimal use of hydrogen through its specifically designed components, maximizing the power and the flexibility of use in the customer application

- Proven track record: based on proven base engine technology familiar technology to use in customers vehicle design and production

KEY FACTS AT A GLANCE

- Max. power: 220 kW (2200 rpm)

- Max. torque: 1000 Nm (1400 - 1600 rpm)

- Hydrogen quality: min. 98% or higher ISO 14687

- H2 consumption: ~19 kg/h @max. power (~12kg/h GenSet)

OUR EXPERTISE, YOUR BENEFIT

All engines and technical data

Sort all our engines by application, power, emission or series to find your engine match.

Search for engines